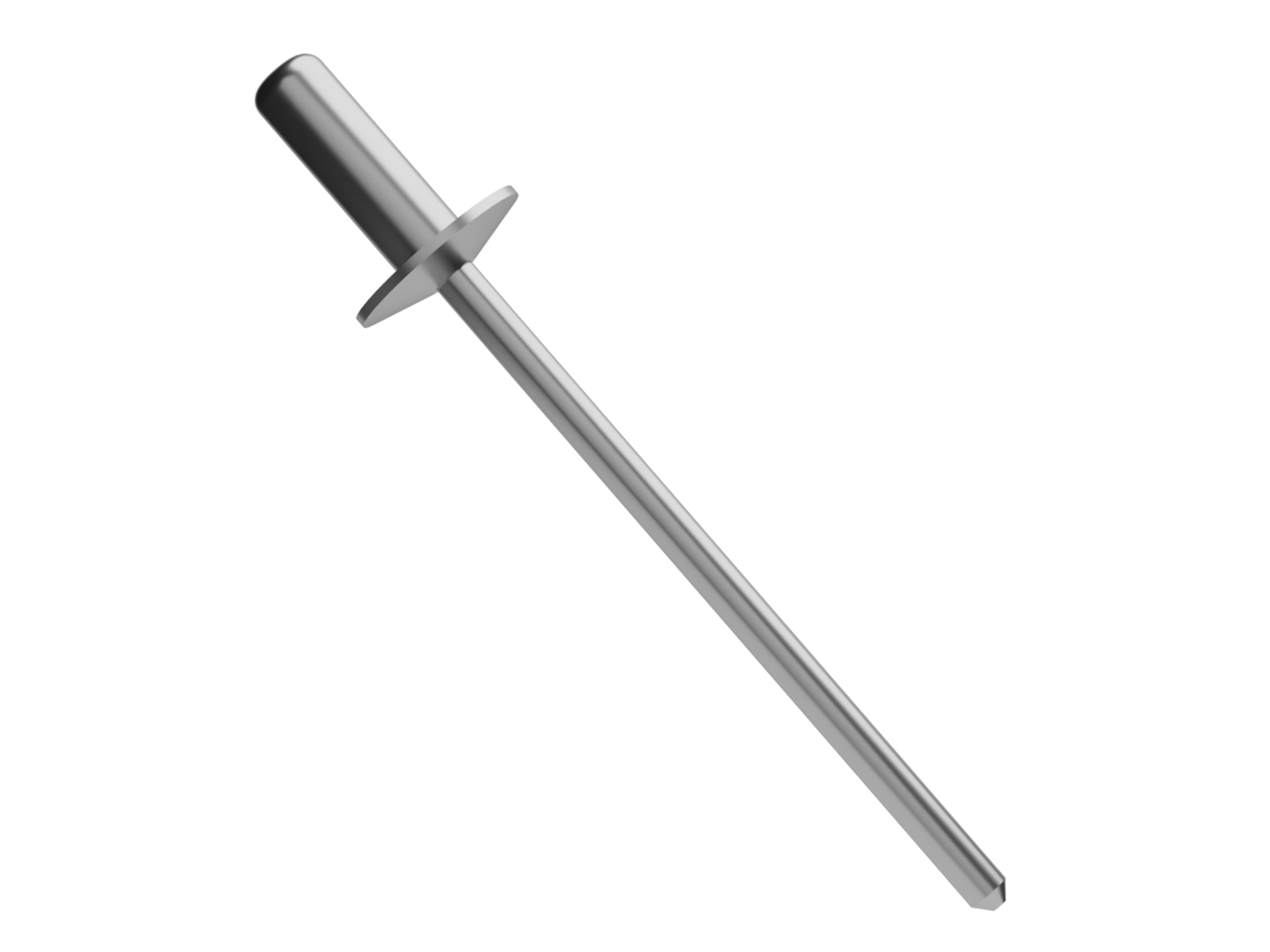

Sealed

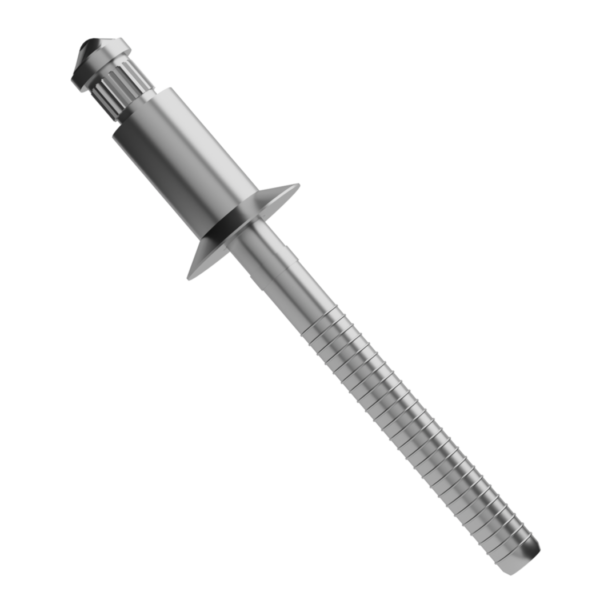

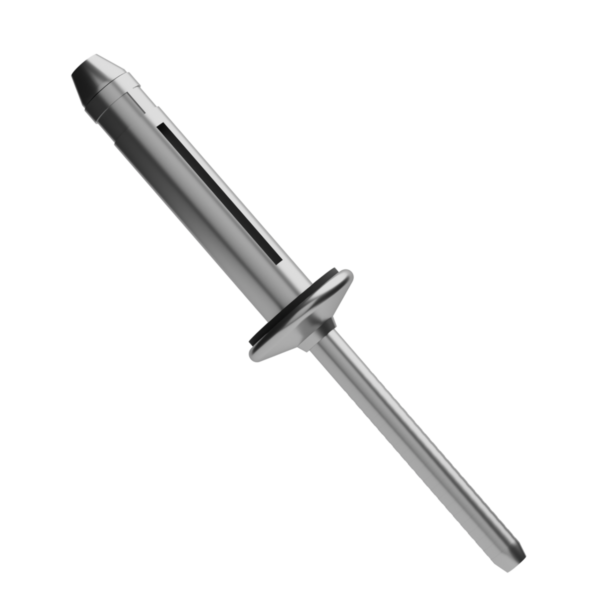

Sealed rivets are specially designed with a closed body bottom to ensure mandrel retention, which also offers excellent sealing properties. Compared to the standard rivet, it provides better mechanical performance.

SELECT MATERIAL AND HEAD TYPE

Ø

3.2 to 6.4 mm

Good sealing to fluids or vapors.

Guaranteed mandrel retention.

Good mechanical behavior.

Great variety of materials.

Automotive,

Industrial vehicles,

Bodies,

Air conditioning and heating,

Construction,

Metal industry,

Metal furniture,

Appliances,

Containers

| Head material | Type | Corrosion conditions | Temperature resistance | Appearance |

|---|---|---|---|---|

| Alu/Steel/Stainless | Lacquering (epoxy or acrylic paint) | Slight | Moderate |

|

| Steel | Passivation zinc plating | Slight | Moderate |

|

| Steel | Passivation zinc plating with sealing | Moderate | Good |

|

| Steel | Zinc-iron coating | Moderate | Moderate |

|

| Steel | Zinc-nickel plating | Severe | Good |

|

| Steel | Special zinc-nickel coating | Very severe | Good |

|

| Aluminum or Steel | Delta seal | Moderate | Moderate |

|

| Aluminum | Aluminum anodizing | Severe | Moderate |

|

| Inox | Stainless steel passivation | Very severe | Good |

|